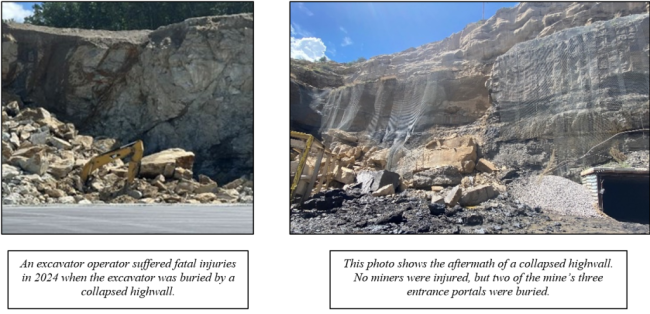

Nine miners have been fatally injured in highwall failure accidents since 2014

Excavator and front-end loader operators, truck drivers and quarry personnel have died when large and small rocks, trees, and entire sections of highwalls have fallen into pits and quarries.

- Root causes include: not examining highwalls prior to beginning work and after rains, snow, and freeze-thaw cycles; not training miners to recognize highwall hazards and practice safe work procedures; highwalls too high to safely maintain or no equipment capable of scaling; working too closely to the highwall; operating equipment with the cab on the highwall side; exiting equipment; and approaching highwalls on foot.

Photo property of MSHA

Best Practices

- Use mining methods that ensure highwall stability and safe working conditions.

- Examine highwalls, spoil banks, and ground that slope into working areas after every rain, freeze, or thaw before working in such areas.

- Scale highwalls to eliminate hazards, e.g., steep slopes or overhangs.

- Operate mobile equipment perpendicular to the highwall or with the operator’s cab positioned away from the highwall. Ensure that miners work, travel, and operate mining equipment at safe distances from the highwall.

- Train miners to recognize hazardous highwall conditions.

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.

Original article published by MSHA