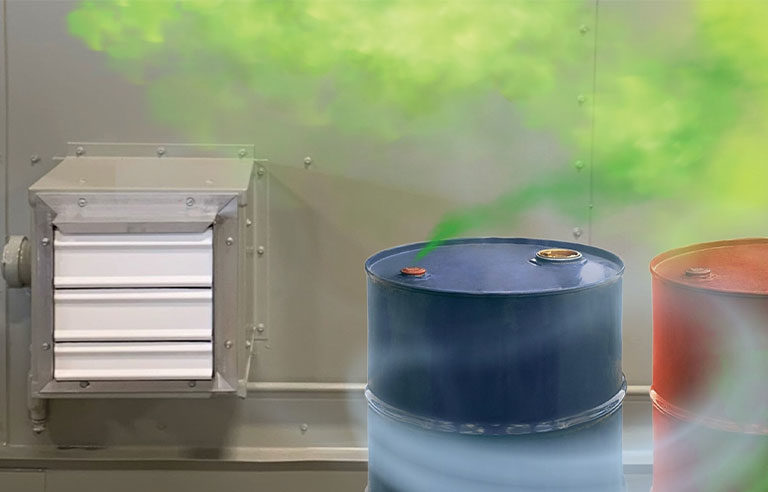

What’s the correct ventilation system for my chemical storage space?

Photo: U.S. Chemical Storage

Responding is Mandy Marxen, commercial marketing manager, U.S. Chemical Storage, North Wilkesboro, NC.

Proper ventilation in chemical storage areas is essential for maintaining safety and compliance. It protects workers from harmful exposure, reduces the risk of fire or explosions, and ensures compliance with regulatory standards. Understanding how to maintain air quality in storage areas where chemicals are stored, handled and/or mixed is crucial.

Maintaining a safe work environment

Ventilation is key to controlling hazardous vapors from toxic, volatile or flammable chemicals. Poor air circulation can lead to dangerous vapor buildup, posing immediate and long-term health risks, causing equipment damage, and/or leading to fires or explosions. Factors to consider:

Chemical properties: Highly volatile or toxic chemicals need more stringent ventilation to prevent vapor accumulation.

Room size and layout: Larger spaces require higher airflow to maintain safe conditions, while smaller rooms can accumulate vapors more quickly.

Activity levels: Frequent handling or dispensing of chemicals increases fumes, requiring higher air exchange rates.

Types of ventilation systems

The right ventilation system depends on the specific chemicals stored and the risks they pose. Common systems include:

Gravity ventilation: A passive method relying on natural airflow. Although inexpensive, it’s insufficient for hazardous materials, as it lacks control over air movement.

Passive ventilation: Uses vents for natural air exchange; suitable for low-risk chemicals but inadequate for highly hazardous environments.

Mechanical ventilation: Uses fans and blowers to actively control airflow, essential for volatile or toxic chemicals.

Explosion-proof ventilation: Designed for flammable chemicals, these systems use nonsparking fan blades and explosion-proof motors to prevent ignition.

Each chemical’s Safety Data Sheet is a critical resource for determining ventilation requirements. The SDS provides information on hazards, including specific ventilation needs.

Volatility: Highly volatile chemicals require higher ventilation rates.

Toxicity: Toxic substances often need enhanced ventilation to protect workers.

Flammability: Flammable materials require explosion-proof ventilation systems.

Regulatory compliance

Proper ventilation must comply with regulations from federal agencies and local building codes. These standards ensure air exchange rates are maintained to protect workers and minimize risk.

OSHA guidelines: The agency outlines ventilation standards for various chemicals, helping manage air quality based on toxicity and flammability.

National Fire Protection Association standards: NFPA 30 and NFPA 400 address ventilation for flammable liquids and laboratories using chemicals.

American Society of Heating, Refrigerating and Air-Conditioning Engineers guidelines: ASHRAE provides ventilation standards for different settings.

Most chemical storage areas require a minimum of six air changes per hour, but highly hazardous areas may need anywhere from seven to 12.

Maintaining the ventilation system

Regular maintenance is essential to ensure your ventilation system functions efficiently and complies with safety standards.

Inspections: Monthly checks help detect issues early. Look for blockages or damage that could restrict airflow.

Lubrication and tightening: Keep moving parts well lubricated and tighten loose components to ensure smooth operation.

Filter maintenance: Clean or replace filters to prevent clogs and maintain airflow.

Emergency equipment testing: Regularly test backup generators and exhaust fans to make sure they work in case of power outages.

Proper chemical ventilation is a critical safety measure. Selecting the appropriate system, adhering to SDS guidelines and maintaining the equipment regularly ensures a safe working environment, protecting both workers and the facility from hazardous incidents.

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.

Original article published by Safety+Health an NSC publication