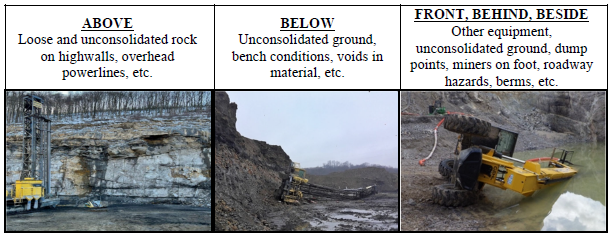

Since the beginning of calendar year 2025, mine operators have reported over 150 accidents from the operation of mobile equipment, including 13 of 20 fatal accidents. Accidents can be prevented by examiners and mobile equipment operators looking for hazards above, below, in front, behind, and beside mobile equipment.

Best Practices

- Perform adequate workplace and ground condition examinations on roadways, benches, unconsolidated ground, and dump sites. Correct hazardous conditions or relocate mobile equipment.

- Perform adequate pre-operational examinations on mobile equipment. If safety defects are found, remove mobile equipment from service until the equipment is repaired

- Follow safe operational practices and parking procedures. Park equipment on level ground. Lower booms and buckets to the ground, and chock mobile equipment wheels.

- Always wear your seatbelt. Do not jump from moving equipment.

- Train mobile equipment operators to be aware of and understand the warnings in the manufacturer’s manual and on mobile equipment decals.

- Ensure the written safety program for surface mobile equipment is updated to address mining conditions or practices that may adversely affect the health and safety of miners or other persons.

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.

Original article published by MSHA