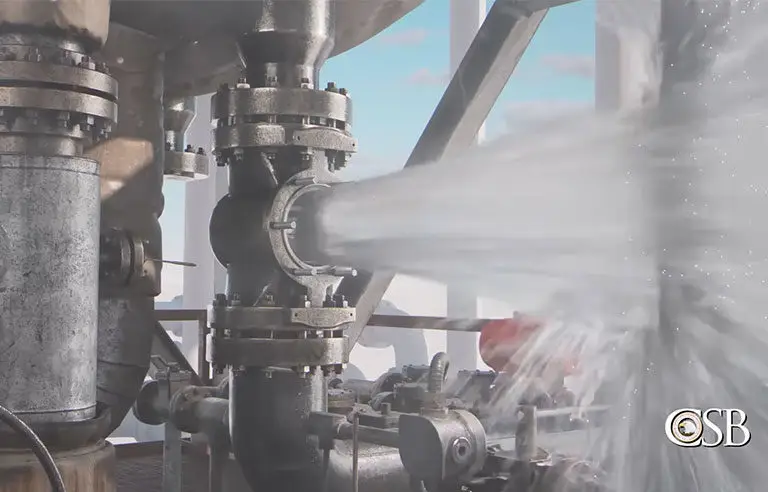

Photo: Chemical Safety Board

Washington — Chemical facilities should clearly mark pressure-retaining components of plug valves and require new valves be designed to prevent the inadvertent removal of these components.

The Chemical Safety Board makes these recommendations in a recently released nine-minute video on a fatal July 2021 release of acetic acid at the LyondellBasell facility in La Porte, TX.

Two workers were killed, another was seriously injured and 29 sought medical treatment after approximately 164,000 pounds of mixture of the corrosive liquid were unintentionally released.

CSB published a final report on the incident in May 2023. An agency investigation determined that three contract workers assigned to repair a leaking pipe inadvertently removed fasteners holding a pressure-retaining valve cover in place when attempting to isolate the pipe, which was positioned near an acetic acid reactor.

Investigators concluded LyondellBasell lacked a detailed procedure on removal of the valve actuator. Further, neither the employer nor the contractor trained workers on its safe removal.

In the video, CSB investigator Benjamin Schrader says that applying Prevention through Design principles for new plug valves is “the best way to address this type of incident.” For existing valves, using color-coded paint and warning signs on pressure-retaining components can lead to easier identification.

Additionally, CSB calls on facilities to promote thorough training. Schrader said conducting a risk assessment may determine that depressurizing and de-inventorying equipment is required before removing parts of a plug valve.

“Vital steps like these can go a long way in injury prevention and help save lives,” CSB member Sylvia Johnson says in the video.

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.

Original article published by Safety+Health an NSC publication