Original article published by MSHA

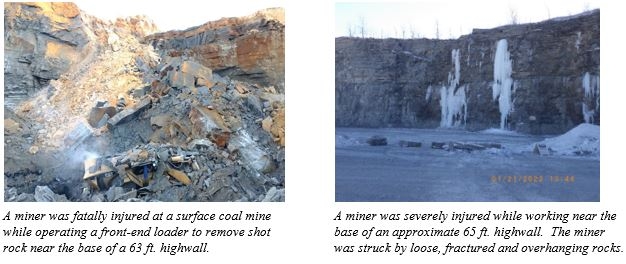

Since CY 2012, falling rocks and materials from hazardous highwalls have resulted in 9 mining fatalities and 27 serious injuries.

Photo property of MSHA

Best Practices

- Develop and follow a plan for the safe control of all highwalls where miners work and travel in close proximity to the highwall.

- Train miners to recognize highwall hazards.

- Conduct highwall examinations and assure hazards (loose rocks, overhangs, trees, etc.) are taken down or supported prior to work or travel near the highwall. Examine more frequently after rain, freezing and thawing.

- Scale highwalls to eliminate hazards, e.g. loose rocks or overhangs. Perform scaling from a position that will not expose miners to injury. Until hazards are corrected, place warning signs or barricades to prevent entry.

- Restrict highwall height to allow available equipment to safely scale the highwall. If benching is necessary, provide adequate bench width based on the type of equipment used for routine clearing or scaling operations.

- Develop blasting plans and use proper blasting techniques. Examine highwalls after blasting.

- Remove trees, vegetation, and unconsolidated material a safe distance from the top edge of highwalls.

- Never park equipment, perform maintenance or store materials beneath highwalls.

- Use diversion ditches or slope the ground so that surface runoff drains away from highwalls.

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.