How can organizations develop a practical lockout/tagout program that addresses electrical energy sources during maintenance?

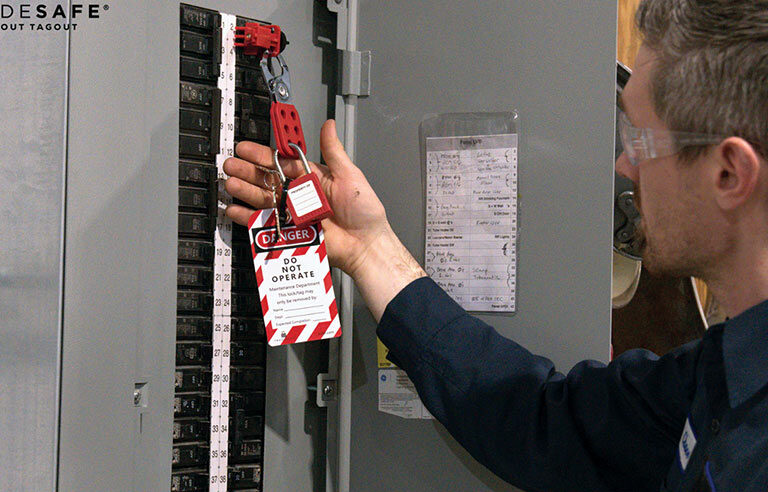

Photo: TRADESAFE

Responding is Herbert Post, vice president, TRADESAFE, Las Vegas.

According to OSHA, proper lockout/tagout prevents 120 fatalities and 50,000 injuries every year. And yet, most programs lack the needed protection for employees. Electrical energy doesn’t make a sound before it kills. That’s what makes it different from other hazards – it’s silent, invisible and often underestimated.

The problem isn’t policy, but practice. Too often, LOTO procedures are developed in isolation: written by someone in an office, checked by someone in legal and filed away for audits. Meanwhile, the electricians and technicians who face the risks are handed generic instructions and expected to follow them perfectly.

How can employers fix this? They can start by treating LOTO as a field tool. Something designed for and by the people doing the work.

Write procedures based on real equipment walkthroughs and workflows

Forget the generic templates. A practical LOTO program starts on the floor – not in an office. Inspect each piece of equipment with the people who service it. Identify every electrical energy source, including secondary feeds, control circuits and stored energy in capacitors or UPS backups.

Ask technicians, engineers and frontline staff where things get confusing or skipped. Make the procedure reflect what they’ll see with the panel open, not what was written years ago when the system was commissioned. Conduct audits as a team and identify improvement opportunities.

Teach workers to verify, not just follow steps

The most dangerous assumption in electrical work is that something is “probably off.” Real training means teaching people how to confirm isolation with a meter or an instrument that detects voltage or current. Every LOTO program should include hands-on training that covers:

- How to test before you touch

- How to recognize stored or residual energy

- What to do if something doesn’t behave as expected

Simulate mistakes. Use real disconnects and panels. If your training never covers what happens when a breaker is mislabeled or a capacitor doesn’t discharge, then your workers are unprepared.

Make accountability a two-way expectation

A practical program doesn’t put all the burden on frontline workers. Supervisors and systems carry responsibility, too. If a worker must choose between shutting down the right way or keeping production moving, that’s a system failure.

Managers must back slowdowns when lockout is necessary. Procedures should include a hard stop if energy verification fails. And workers should be encouraged to speak up without fear when they spot a gap, because that’s how lives get saved.

Lastly, management must provide lockout devices, tags, instruments and tools to employees and make sure they’re being used properly. If employees don’t have LOTO tools, they’ll perform unsafe acts.

LOTO doesn’t exist to satisfy paperwork but to protect the worker standing in front of an energized panel, trusting that system to keep them alive. If your team can’t apply it confidently in those conditions, it’s not a practical program yet. But it can be if you build it with them, for them and with electricity in mind.

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.

Original article published by Safety+Health an NSC publication