Report number: 16NY064

Issued by: New York Fatality Assessment and Control Evaluation Program

Date of report: Oct. 6, 2021

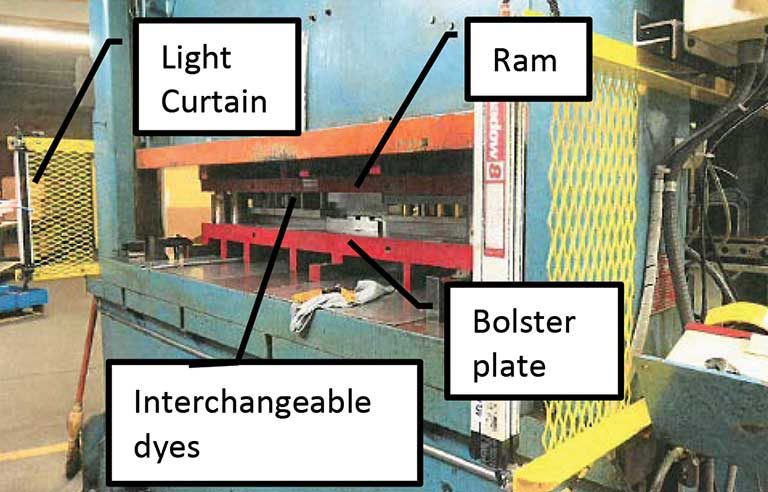

A worker at a manufacturing facility was fatally injured while operating a 200-ton mechanical press. The worker and another employee were making bus bars, a component of electrical devices, out of raw copper strips. The mechanical press frequently jammed, requiring the worker to place two safety blocks between the ram and bolster and reach into the press to unjam it. The worker would then remove the safety blocks and actuate the machine at a dual-button control panel mounted to a pedestal in front of the long side of the press. The workers had to unjam the press multiple times. The last time they removed the jam, the safety blocks were unintentionally left on the bolster bed. The worker, who was standing in front of the press by the pedestal controller, actuated the press. The two safety blocks were immediately ejected from the press. One struck the worker in the neck and chest, causing severe injuries. A 911 call was made, and another employee tried to help using basic first aid. Emergency responders arrived within minutes, but the worker died at the scene. Cause of death was listed as blunt force injuries to the neck.

To help prevent similar occurrences, employers should:

- Ensure interlock devices are used in conjunction with safety blocks on mechanical power presses.

- Ensure the selected safety blocks meet the rated capacity of the specific power presses.

- Center safety blocks along middle length of press when servicing.

- Ensure press controls are moved to short ends of press to avoid risk of being struck by ejected materials.

- Design machine guarding that allows for safe movement around machinery.

- Implement a maintenance and inspection schedule for mechanical presses.

- Ensure employees are thoroughly trained on machines they operate.

- Conduct a job hazard analysis for specific tasks and instruct employees on how to safely work with and troubleshoot machinery issues.

- Train employees on lockout/tagout procedures.

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.