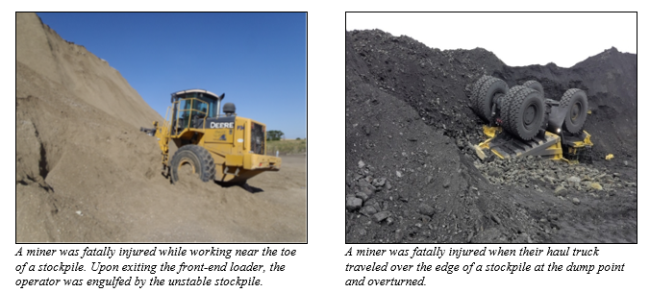

Recent accidents highlight the risks associated with dump points and stockpiles, especially where stockpile stability and visibility are of concern. Fatalities and serious injuries have occurred when heavy equipment operators traveled or dumped material too close to a stockpile edge or worked too close to the toe of an over-steepened stockpile.

Best Practices

- Examine stockpiles and dump sites for signs of instability or other hazards before starting operations. Examine berms, ramps, stockpile slopes, and dump and toe areas throughout each shift.

- Provide adequate lighting at dump points and on stockpiles, especially during low-light conditions.

- Provide positive wheel stops or berms to prevent backing over the edge of a stockpile

- If a wheel stop is not provided, use a spotter or dump material at a safe distance from the edge and push the material over with a bulldozer.

- Train all workers to recognize and eliminate or control hazards when working near dump points and stockpile areas.

- Never load out from a stockpile’s toe when dumping above.

- Stay clear of stockpile toes except when loading.

- Control stockpile size and shape to reduce the risk of material sloughing or sudden collapse. Regularly reconfigure stockpiles to promote stability.

- Establish safe traffic patterns including designated pathways for equipment. Always keep a safe distance from dump points and active stockpiles.

- Maintain clear communication between operators and spotters.

- Use mirrors, cameras, or radar systems to maintain visibility around equipment and other vehicles.

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.

Original article published by MSHA