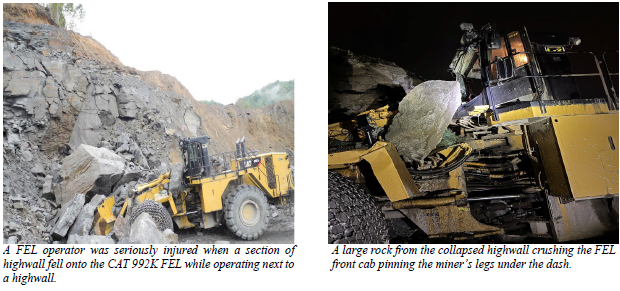

Highwall Failure Accident

On September 30, 2024, a miner sustained permanently disabling injuries while operating a Caterpillar 992K front-end loader (FEL) beneath a highwall. A roughly 50-ft. section of highwall fell onto the FEL crushing the cab and pinning the miner’s legs under the dashboard.

Best Practices

- Develop and follow procedures for the safe control of all highwalls where miners work and travel in close proximity to the highwall.

- Train miners to recognize highwall hazards.

- Conduct highwall examinations and eliminate hazards (loose rocks, overhangs, trees, etc.) prior to working or traveling near the highwall. Examine highwalls from multiple perspectives (bottom, sides and top/crest). Examine highwalls more frequently after rain events and periods of freezing and thawing.

- Use auxiliary lighting during low light conditions to conduct highwall examinations and illuminate active work areas.

- Never park equipment, perform maintenance or store materials beneath the highwall.

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.

Original article published by MSHA