Are quick coupling devices used on your worksite to change excavator buckets and other attachments?

Quick couplers are common in construction work. However, buckets or attachments may unintentionally fall from excavators because of improper securement of the bucket or attachment, mechanical or hydraulic failure in the coupler, or unsafe opening of the coupler by the operator, NIOSH says.

Among the agency’s tips:

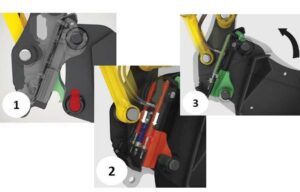

- Use quick couplers manufactured with design features and processes to prevent the unintentional release of buckets or attachments, such as models with alerting systems to signal whether the connection was successful.

- Follow manufacturers’ guidelines for equipment when planning job tasks. For example, many manufacturers state that ground workers shouldn’t be within the swing radius/swing zone of an excavator arm.

- Ensure machine operators always conduct visual inspections on the excavator and quick coupler before starting work. Remove from service any excavator with functional issues and tag it with a “Do not operate” sign.

- Establish communication methods between the excavator operator and ground workers before starting work.

- Make sure operators lower the excavator arm to the ground before exiting the cab.

NIOSH encourages employers, supervisors and equipment suppliers to “share and apply these recommended practices at the worksite.”

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.

Original article published by Safety+Health an NSC publication