Photo: TRADESAFE

Responding is Herbert Post, vice president, TRADESAFE, Las Vegas.

Wearables are no longer futuristic technologies. They’re now reshaping how safety is seen, measured and implemented in various industries in real time.

Take the case of TotalEnergies, a global multi-energy company. Resolving equipment issues often would require shutting down operations until experts arrived. This meant exposing workers to prolonged hazards in these high-risk environments. On top of increased downtime and higher costs for maintenance, worker safety is at risk in this scenario.

As a solution, the company decided to deploy wearable headsets equipped with video cameras, microphones, headphones and sensors that monitor environmental and physiological data. This solution enabled hands-free, real-time remote collaboration through an integrated communication platform, allowing onsite technicians to connect instantly with global experts for live testing, document access and guidance without interrupting their tasks. The company experienced reduced exposure to hazards, faster resolutions of issues and improved proactive monitoring of workers’ health.

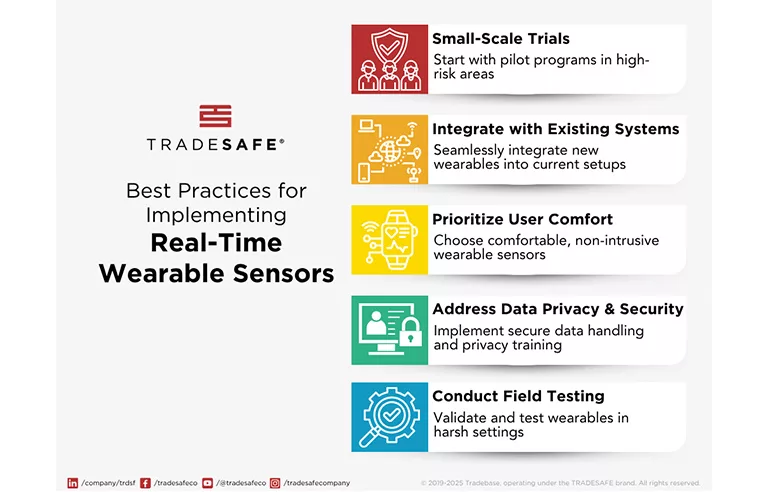

Now, how can other organizations do the same and implement real-time wearable sensors to enhance worker safety? They should:

Start with small-scale trials in high-risk areas. For utility operations, this means conducting pilot programs for critical tasks such as substation patrols or line work. The main goals are to evaluate if the wearable sensors are feasible during those tasks, rack up as much feedback as possible and then measure the outcomes.

Integrate wearable sensors with existing systems. Going back to the case of the global multi-energy company, it’s clear that TotalEnergies already had existing IoT systems, and adding the new wearable would have required it to seamlessly integrate the new tech into those systems. The main purpose is to make sure the wearable sensors are compatible with existing systems, enhancing real-time hazard detection.

Prioritize user comfort and adoption. The reality on the floor is that it doesn’t matter how advanced a wearable technology is. If it gets in the way or hinders the job, then workers are more likely not to wear or use it properly. Choose comfortable, nonintrusive wearable sensors, and make sure to provide proper training.

Address data privacy and security. If there’s one big red flag for workers when it comes to wearable sensors, it’s the issue of data privacy and security. It’s important to implement consent protocols, secure data handling and privacy training to build trust and comply with regulations.

Conduct thorough field testing. Validating and testing wearable sensors in harsh settings will evaluate the devices’ integrity and accuracy, as well as minimize false alarms. The primary objective is to make sure the sensors will work even in the harshest conditions that the worker would be in.

The key takeaway?

Implementing wearable sensors should focus on worker safety. If safety is the goal, then integrating it with current setups will go easier than expected for most utilities. The real challenge is to make sure workers understand that these sensors are there to watch their backs. Do that, and adoption will be seamless.

McCraren Compliance offers comprehensive safety training to help prevent accidents. Visit our class calendar to see how our training and consulting services can enhance your safety efforts.

Original article published by Safety+Health an NSC publication