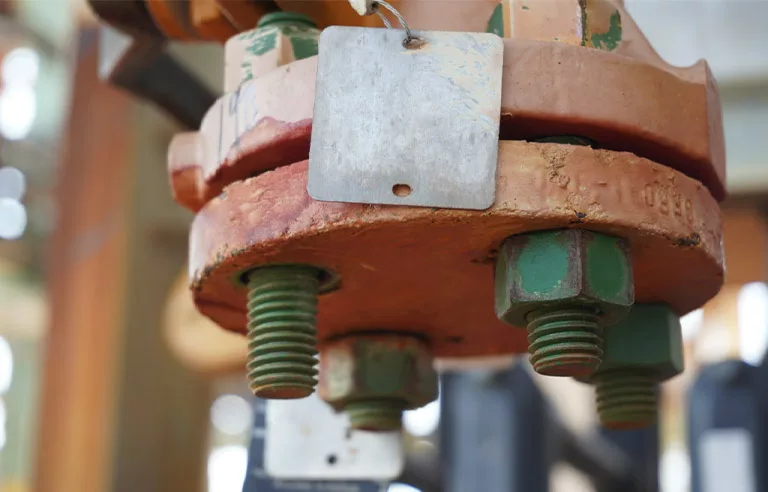

Figure 30. Blind flange as found after the incident. One nut was removed (foreground left) and another (background left) was loosened to within two to three threads. (Credit: CSB)

Washington — When chemical facility operators find flawed equipment, it’s “not enough to simply identify a deficiency if that deficiency goes unmanaged and unmitigated,” the Chemical Safety Board says.

The agency recently published a final report exploring three separate incidents involving toxic hydrogen fluoride at the Honeywell Performance Materials and Technologies facility in Geismar, LA. The events occurred between October 2021 and June 2024 and “reveal systemic safety failures at the facility.” They led to a worker death, a serious injury and millions of dollars in property damage.

In the fatal incident, a corroded flange gasket failed during startup, spraying hydrogen fluoride onto the worker’s face, ear and neck. Investigators found that although the facility had known since 2007 that the gasket material was susceptible to corrosion and conducted management-of-change evaluations, it “elected to wait to replace the gaskets until the gaskets could either be replaced opportunistically and proactively during future maintenance efforts or when the gaskets would run to failure.”

CSB reports that the worker – who died the next day – wasn’t wearing sufficient personal protective equipment.

Hydrogen fluoride can cause serious injury or death at a concentration of 30 parts per million, the agency says. Exposure to the substance may cause lung disease, skin damage and visual impairment, among other adverse health conditions, according to the Centers for Disease Control and Prevention.

To prevent future incidents, CSB recommends facilities develop and maintain “thorough” mechanical integrity programs with testing and inspection protocol that help “successfully identify and resolve equipment deficiencies prior to failure.”

Other recommendations:

- Organizations should ensure their mechanical integrity programs communicate the need for corrective action to all stakeholders when safety-critical equipment is either approaching or has reached a point that requires corrective action.

- Employers should develop and implement systems to manage organizational and personnel change. It’s crucial to ensure process safety-related responsibilities and tasks aren’t lost during such changes.

- To ensure one incident doesn’t cause or lead to another, employers should develop and implement resilience programs to recognize and prevent or minimize disruption to their routine process safety management activities and other systems that contribute to process safety.

CSB calls on the Environmental Protection Agency to initiate a review of hydrogen fluoride under the Toxic Substances Control Act to explore potential health and environmental risks. The board also recommends that OSHA amend its standard on process safety management of highly hazardous chemicals (1910.119) to require management of change reviews for organizational changes impacting process safety.

“Not only were these three serious incidents completely unacceptable,” CSB Chair Steve Owens said in a press release, “our investigation found that they also were entirely preventable.”

McCraren Compliance offers many opportunities in safety training to help circumvent accidents. Please take a moment to visit our calendar of classes to see what we can do to help your safety measures from training to consulting.

Original article published by Safety+Health an NSC publication