How can organizations verify that employees not only receive chemical safety information but truly understand and can act on it?

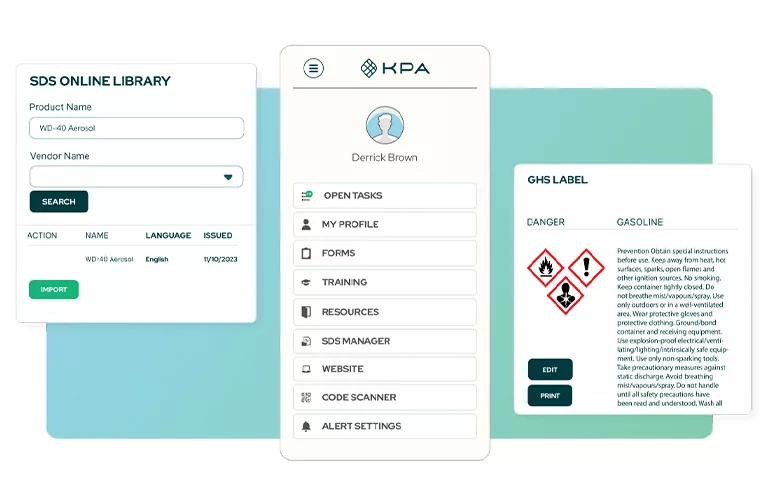

Photo: KPA

Responding is Marian Kochin, CSP, content writer, training and content team, KPA, Westminster, CO.

To truly understand the risks associated with chemicals and other hazardous materials in their workplace, employees need more than dusty binders or verbal reminders.

Organizations must ensure hazard details and protective measures are both clearly documented and actively understood by those who work with chemicals every day.

To achieve a level of actionable understanding among employees, employers must make safety information accessible and accurate, deliver comprehensive training that goes beyond the basics, and verify comprehension by measuring engagement and collective feedback.

Ensure chemical safety information is accessible and accurate

Employees can’t follow chemical safety procedures if they don’t have reliable information at their fingertips. Usually, that information comes in the form of Safety Data Sheets. Some employers keep their SDSs in a binder, while others provide access electronically.

SDSs contain a range of important information for employees and other audiences, including safety and health professionals, emergency responders, government agencies, and consumers. The sections at the beginning of an SDS highlight the most critical details for workers and emergency responders, while the later sections provide more technical background.

Simply keeping SDSs onsite isn’t enough, though. They require active upkeep to ensure information remains current. For example, say a manufacturer tweaks a chemical formula and updates its handling precautions accordingly. If an organization then fails to update the corresponding SDS, employees and emergency responders might depend on outdated guidance when an emergency strikes.

Centralize SDSs for faster emergency response

Digital SDS systems help ensure accuracy. By centralizing SDSs in a digital library, automatically updating them across all locations and making them easy to search on any device, organizations give workers and first responders instant access to the most accurate chemical information.

The result? Employees have the most-up-to-date information at their fingertips, and they can initiate faster, safer incident response.

Deliver training that goes beyond the basics

Although SDSs are one tool that organizations can use to ensure chemical safety, robust training programs help ensure employees understand the risks and procedures associated with chemicals and other hazardous materials.

And although OSHA’s standard on hazard communication (1910.1200) requires that employees receive training when they’re first assigned to work with hazardous chemicals and whenever new hazards are introduced, the most successful programs go even further with engaging refresher courses, periodic toolbox talks and in-depth emergency simulations.

Finally, employers can deploy mobile-friendly modules that offer daily microlearning lessons to help employees retain information and apply it in real-life situations. That ensures they don’t just hear safety information once, but review, understand and act on it every day.

Verify comprehension through engagement and feedback

Even the best training programs can fall short if organizations don’t confirm employees understand the material. Verification requires moving beyond sign-off sheets or attendance logs. Instead, organizations should build in “checkpoints” (short quizzes, scenario-based drills or live demonstrations) to measure comprehension in real time.

Feedback from these exercises gives leaders insight into where additional training is needed. That goes both ways: Employees often spot gaps or risks that leadership can’t see. By creating and maintaining open channels between frontline employees and safety leaders, organizations can increase chemical safety engagement, build trust and refine critical procedures so they work for everyone.

By delivering clear safety information through SDSs, conducting frequent trainings, and measuring both engagement and outcomes, employers can be confident that employees will act on their chemical safety knowledge.

At McCraren Compliance, we offer a variety of safety training programs to help reduce the risk of accidents. Take a moment to check out our class calendar and see how our training and consulting services can support your safety goals.

Original article published by Safety+Health an NSC publication